News

Research has found that over 90% of vehicle accidents are caused by human factors. In order to reduce the occurrence of accidents and casualties, the European Union has issued a series of regulations aimed at protecting vulnerable road users (pedestrians outside the vehicle, cyclists, etc.), reducing traffic accident rates and casualties.

UN Regulation No. 158 specifies technical requirements for the reverse device of M and N class vehicles and the driver's rear view of the vehicle when reversing. This regulation will come into effect on June 10, 2021 and will be mandatory from July 6, 2022.

UN R158 Scope of Application

Component level: For reverse facing visual devices used for installation on M and N class vehicles, specific requirements shall be implemented in accordance with Part I of this regulation.

Vehicle level: For M and N class vehicles equipped with rear facing visual devices and reverse warning systems, specific requirements shall be implemented in accordance with Part II of this regulation.

Other categories: At the request of the manufacturer, contracting parties may approve vehicles of other categories and devices installed on these vehicles in accordance with Part I and Part II.

Reverse system configuration and certification requirements

Table 1. Configuration and certification requirements for reverse system:

Note: If the actual situation is a combination of multiple devices, it is required that each component has a certificate and all vehicle testing projects are completed in order to obtain the R158 vehicle certificate.

Figure 1. Rearview Mirror Camera System (RVCS)

Figure 2. Reverse detection system

-

In the whole vehicle certification, according to the requirements of the reverse warning system and visible area, the testing methods are divided into close range rear view testing and whole vehicle detection area testing:

1. Requirements for vehicle close-up rearview testing:

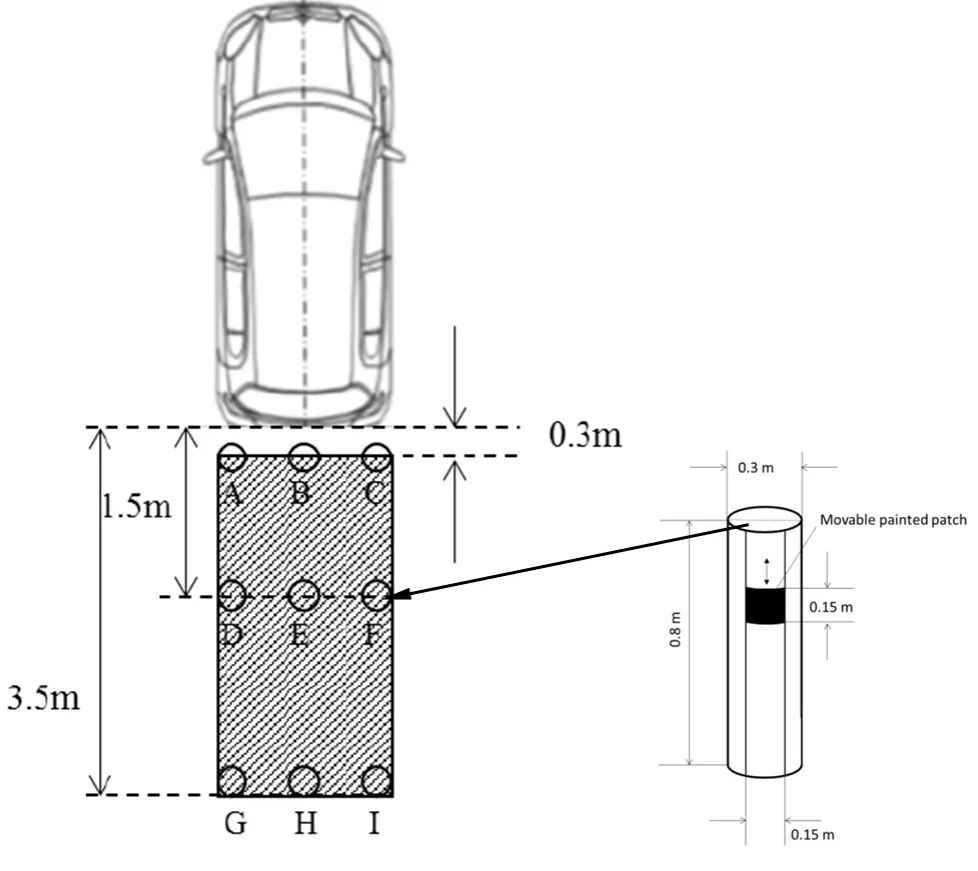

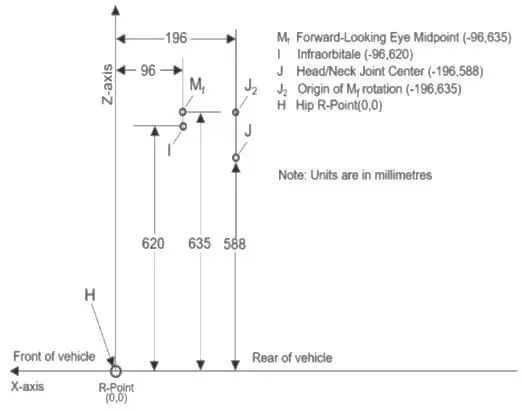

Within a field of view of 0.3m to 3.5m that is consistent with the width of the vehicle at the rear (Figure 3), the driver's position test reference point shown in Figure 4 is used for testing with the help of tools. The requirements are:

(a) The three test objects closest to the test vehicle are in the first row, and it is required to be able to observe at least one 0.15m * 0.15m area in each test object, or the top of the test object. (b) For the test objects in the second and third lines, it is required to be able to observe the entire test object.

Figure 3. Requirements for the field of view of the vehicle at close range

Figure 4. Driver Position Test Reference Point

2. Vehicle detection area testing requirements:

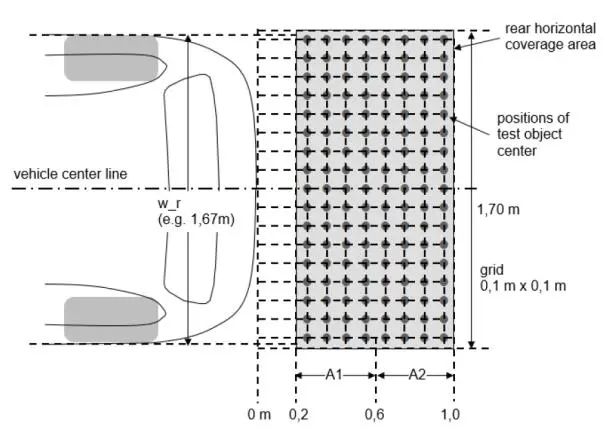

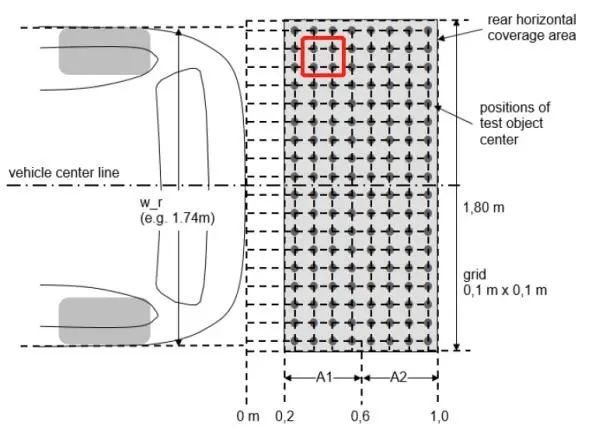

Within the detection area of 0.2m to 1.0m from the outermost point at the rear of the vehicle that is consistent with the width of the vehicle. Divide by the width of the vehicle (rounded: 1.7m for 1.67m, 1.8m for 1.74m, odd width: test object placed on the centerline of the longitudinal axis; even width: test object placed on both sides based on the centerline of the longitudinal axis), create a 0.1mx0.1m grid in the above area, and place the test object on the grid.

(a) The area between 0.2m and 0.6m is A1 area, and the total number of detections is required to be ≥ 90%;

(b) The area between 0.6m and 1.0m is A2 area, and the total number of detections is required to be ≥ 87%;

(c) There should be no undetected object in a square composed of grids larger than 2 * 2 (see Figure 6).

Figure 5. Requirements for testing the detection area of the entire vehicle (odd width of the vehicle)

Figure 6. Requirements for testing the detection area of the entire vehicle (even width of the vehicle)

I believe that after the implementation of a series of regulations, the number of casualties in road traffic accidents will be significantly reduced. Above, we have briefly analyzed the test content of the reverse device for you. For more information, please feel free to contact us!

![]() In today's industrial and technological development, efficient motor technology has become a key factor driving innovation. Especially in the field of high-speed motors, the requirements for technology are even more stringent. Today, we will explore an important and cutting-edge topic - the high-speed single motor test bench. This article not only represents the latest progress in motor technology, but also has a profound impact on the development of the entire industrial automation and electric vehicle industry.2024-04-10 13:32:33

In today's industrial and technological development, efficient motor technology has become a key factor driving innovation. Especially in the field of high-speed motors, the requirements for technology are even more stringent. Today, we will explore an important and cutting-edge topic - the high-speed single motor test bench. This article not only represents the latest progress in motor technology, but also has a profound impact on the development of the entire industrial automation and electric vehicle industry.2024-04-10 13:32:33![]()

Rock Fashion Night | Zhejiang Eco 2024 Annual Conference Celebration Exciting Review

Taking inspiration from its unique rock fashion style, this annual conference perfectly embodies the corporate spirit of Eco: full of motivation and vitality, daring to break through conventions, and constantly pursuing innovation. The on-site decoration of the evening party is fashionable and full of rock style, and every employee is dressed in formal attire, shining brightly. The group photo area and check-in area have become popular locations for taking photos and reminders, with every corner recording the laughter and excitement of the employees.2024-04-10 11:08:46![]()

Charging towards the New, Breaking Dawn | Zhejiang Eco's 2023 Employee Summary and Commendation Conference Successfully Ends

On the afternoon of January 29, 2024, the 2023 Employee Summary and Commendation Conference of Zhejiang Eko Automotive Technology Service Co., Ltd. was grandly held at the company headquarters Jinghua Chuangming Space. Leaders at all levels and employees from various departments of the company gathered together to review the achievements of the past year, commend individuals and teams who have made outstanding contributions, and work together to plan for 2024.2024-04-10 10:42:42![]()

ATTC News | Zhejiang Eco&Shanghai Industrial Innovation Center Intelligent Connected Vehicle OTA Joint Experimental Platform Launch Ceremony Successfully Ends

On January 16th, the launch ceremony of the "Unlimited Online Connected Intelligent Leading Car Tour" Intelligent Connected Vehicle Forum and the Shanghai Industrial and Technological Innovation Center and Zhejiang Eko Intelligent Connected Vehicle OTA Joint Experimental Platform was successfully concluded at the Shanghai Industrial and Technological Innovation Center. Wang Tianguang, Director of the Shanghai Municipal Administration of Communications, Bi Cong, Director of the Infrastructure Construction and Management Department of the Shanghai Municipal Commission of Science and Technology, and Zhou Aiqing, Deputy Director of the Jinqiao Management Bureau of the China (Shanghai) Pilot Free Trade Zone Management Committee, attended speeches and unveiled the plaque for the Intelligent Connected Vehicle OTA Joint Laboratory.2024-04-10 13:39:55![]()

ATTC Technology Sharing | Brief Description of Warning Light Frequency Requirements

Warning lights use electronic technology to rotate or flash the light source to serve as a reminder. Commonly installed in special vehicles such as ambulances, fire trucks, police cars, and engineering vehicles.2022-10-26 11:43:46![]()

ATTC Technology Sharing | Introduction to Gearbox Torsion Fatigue Test

The reducer is one of the key components in automobiles, mainly used to reduce speed, transmit power, and increase torque. Most gear transmission products will experience slight fatigue cracks and wear on the surface of their tooth surfaces during long-term operation, resulting in pitting corrosion. Initial pitting can reduce the load-bearing area of the tooth surface, causing impact and noise. However, destructive pitting and surface peeling, once they occur and expand, may lead to tooth surface damage, unstable gear operation, intensified vibration of the reducer, and increased transmission noise. When the damage reaches a certain level, it may lead to gear breakage, especially critical gear damage, which can cause serious consequences such as damage to the entire transmission system or mechanical components.2022-10-26 11:41:25